I do a lot of baking and use a lot of vanilla. I like to know where my food comes from and what's in it, but vanilla has been confusing me. Some of my friends are making or wanting to make their own vanilla extract because store bought vanilla contains vanillin. I've heard vanillin comes from the waste products of a paper factory. Yuck! And from the article below (last sentence) it can also come from cow dung. Even more Yuck! And now today someone tells me that my yummy precious Kirkland Signature Vanilla Extract contains vanillin. What's a girl to do??? or eat for that matter? Research. I started by studying the wording on my Kirkland bottle.

Ingredients: Vanilla Bean Extractives in Water, Alcohol (35%) and Sugar.

I don't see any vanillin in there, but wait, examine the wording on the side of the bottle:

It looks like there is some sort of vanillin in there after all. I did several Swag Buck searches on vanillin and from what I've read it looks like there are two kinds, natural vanillin and synthetic vanillin. It's the synthetic vanillin that you want to stay away from and from what I can tell Kirkland contains natural vanillin. Phew! I'm safe. Now I can go to sleep :)

I would love to hear what you think about vanilla and vanillin. I did a quick search of my pantry and couldn't find anything with vanilla or vanillin. I suspect they hide it under the term 'artificial flavoring'. Search your pantry and tell me what you find.

This info came from Wikipedia.

Natural production

Natural vanillin is extracted from the seed pods of Vanilla planifola, a vining orchid native to Mexico, but now grown in tropical areas around the globe. Madagascar is presently the largest producer of natural vanillin.

As harvested, the green seed pods contain vanillin in the form of its β-D-glycoside; the green pods do not have the flavor or odor of vanilla.[20]

After being harvested, their flavor is developed by a months-long curing process, the details of which vary among vanilla-producing regions, but in broad terms it proceeds as follows:

First, the seed pods are blanched in hot water, to arrest the processes of the living plant tissues. Then, for 1–2 weeks, the pods are alternately sunned and sweated: during the day, they are laid out in the sun, and each night, wrapped in cloth and packed in airtight boxes to sweat. During this process, the pods become a dark brown, and enzymes in the pod release vanillin as the free molecule. Finally, the pods are dried and further aged for several months, during which time their flavors further develop. Several methods have been described for curing vanilla in days rather than months, although they have not been widely developed in the natural vanilla industry,[21] with its focus on producing a premium product by established methods, rather than on innovations that might alter the product's flavor profile.

Vanillin accounts for about 2% of the dry weight of cured vanilla beans, and is the chief among about 200 other flavor compounds found in vanilla.

[edit]Chemical synthesis

The demand for vanilla flavoring has long exceeded the supply of vanilla beans. As of 2001, the annual demand for vanillin was 12,000 tons, but only 1800 tons of natural vanillin were produced.[22] The remainder was produced by chemical synthesis. Vanillin was first synthesized from eugenol (found in oil of clove) in 1874–75, less than 20 years after it was first identified and isolated. Vanillin was commercially produced from eugenol until the 1920s.[23] Later it was synthesized from lignin-containing "brown liquor", a byproduct of the sulfite process for making wood pulp.[9] Counter-intuitively, even though it uses waste materials, the lignin process is no longer popular because of environmental concerns, and today most vanillin is produced from the petrochemical raw material guaiacol.[9] Several routes exist for synthesizing vanillin from guaiacol.[24]

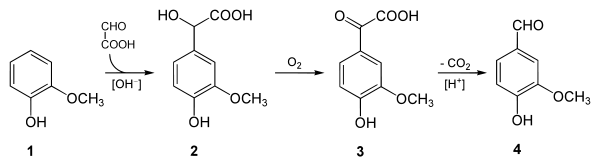

At present, the most significant of these is the two-step process practiced by Rhodia since the 1970s, in which guaiacol (1) reacts with glyoxylic acid by electrophilic aromatic substitution. The resulting vanillylmandelic acid (2) is then converted via 4-Hydroxy-3-methoxyphenylglyoxylic acid (3) to vanillin (4) by oxidative decarboxylation.[4]

In October 2007 Mayu Yamamoto of the International Medical Center of Japan won an Ig Nobel Prize for developing a way to extract vanillin from cow dung.[25]

Thanks, Ginny. Now I can sleep too knowing you and your family haven't been eating cow dung.:) Maybe now I will venture out and buy the one from Costco. Andrea

ReplyDelete